Chainveyor® offers a variety of control options. From component-level VFD’s to turn-key, fully automated systems we can provide the level of controls you require.

Variable Frequency Drives

Chainveyor® Variable Frequency Drives (VFD) are available for new and existing systems. The variable frequency drive utilizes a state of the art AC frequency controller with motor and gear reducer combination to provide maximum output speed range.

It offers these great advantages:

- Easy speed change with push button control

- Reduces maintenance by eliminating many of the mechanical drive parts such as variable pitch sheaves, V-Belts, and torque limiters. The VFD controller electronically controls speed and limits output torque to preprogrammed levels.

- Broad speed range. Variable Frequency Drives allow speed ranges up to 20:1 (older technology mechanical variable pitch sheaves have a speed range of less than 2:1).

- Improved Gearmotor Design. High efficient helical gear reducers with Inverter Duty TEFC motors all full torque rating at a broad range of speeds with less heat buildup than double worm gear reducers.

- Full Function VFD controller. Variable Frequency Drives offer full function options such as soft starting, torque limiting and overload protection.

Specification and Options

| Power Requirement | 230/480 Volt, 3 Phase, 50/60 Hertz | |

| Motor | ¼ HP or 2 HP TEFC Inverter Duty Integrally Mounted or Optional C-Face | |

| Gear Reducer | Parallel Helical Gear Motor, Ratios 726:1 or 80:1 | |

| Chain Speed Range* | Low Speed: 0.6 – 13.0 FPM; High Speed: 6.0 – 100 FPM | |

| VFD Enclosure | Open Chassic. IP 20 Enclosure for subpanel or DIN rail mounting. Din rail mounting plate is available. | |

| Remote Key Pad (Optional) | NEMA 4 Full Function Key Pad | |

| Adapter Kits (Optional) | For converting existing system, Includes: Adapter Plate, Gearmotor, and Variable Frequency Controller | |

*Speed Range varies depending on drive arrangement and load.

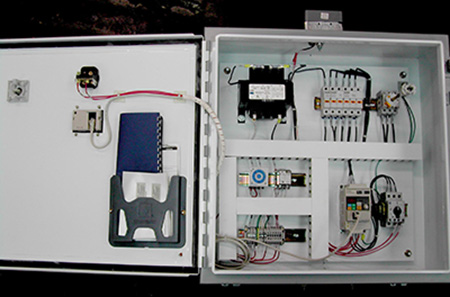

Control Panels

From basic system Start / Stop functionality to panels with Human Machine Interface (HMI), Chainveyor®’s designers can provide you with the right equipment to control your Overhead Conveyor. Interlocks can also be provided to communicate with adjoining equipment.

Turn-Key Overhead Conveyor Systems

No matter your requirements, Chainveyor® can provide the right level of support for your needs. From component level to turn-key solutions, we can accommodate your needs by providing support from concept through implementation.

Tell us about your project.

Our goal is to not only provide the equipment you need, but to help you develop a comprehensive solution.

In designing your custom conveyor system solution, we focus on your needs, your business, and your budget.